SHARE

Computer Vision in Manufacturing: Opportunity or Threat?

Product quality is a prime concern for any manufacturing process. In every manufacturing facility, the quality control division plays a big role. Traditionally most quality control activities are done by humans. However, there are some human activities held by operators that are in fact inhuman. See the left figure below. It is difficult for humans to identify defects by continuously looking at products through a conveyor. It is not only costly also not safe for the person involved. Nowadays, with technology development, it is possible to monitor almost everything. Therefore, most manufacturing processes have replaced the human vision by computer vision in order to make quality control decisions.

The system consists of computer hardware and software together with cameras and lighting to capture images that are then algorithmically compared to a predefined image or quality standard. The figure to the right side shows the use of computer vision in finding defects in filling. Half-filled/overfilled bottles or incorrectly printed labels can be detected by a computer vision system located in the process line.

Visual control

Visual control

Source: http://www.opli.net/opli_magazine/imaging/2013/close-inspection-of-vehicle-components-vision-2014-news/

Source: http://www.opli.net/opli_magazine/imaging/2013/close-inspection-of-vehicle-components-vision-2014-news/

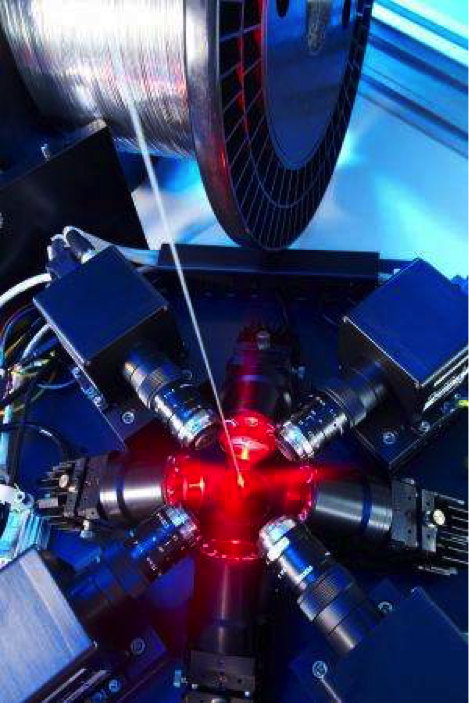

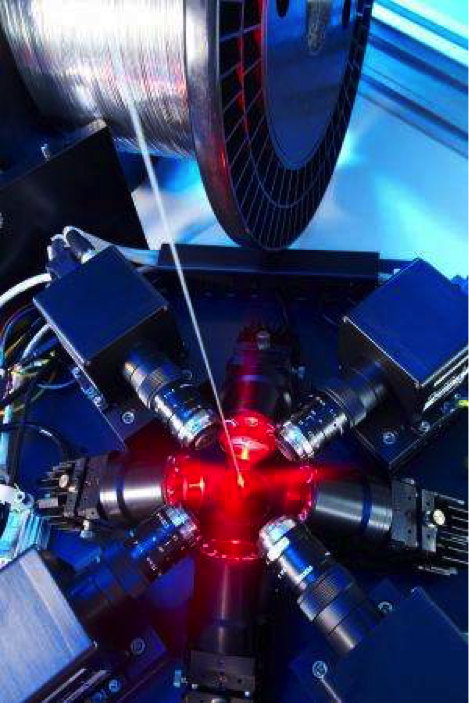

Strip products are long workpieces such as pipes, rails, wires, or boards that are manufactured at high flow velocities. The speed of production and the small size of the object creates a big difficulty in quality control however successfully addressed by the computer inspection system as shown below for fire manufacturing.

Source: http://phys.org/news/2014-04-optical-wire-pipe-rails-meters.html

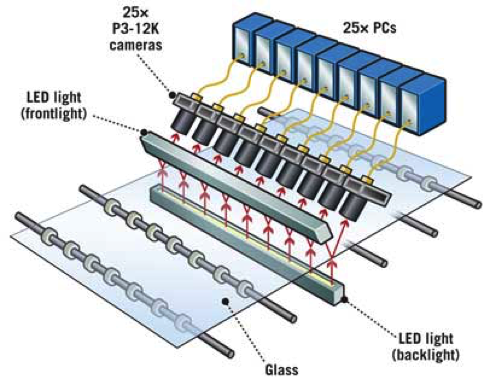

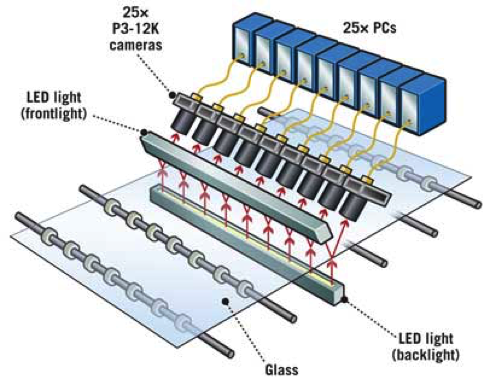

Glass sheets; another difficult application. See below figures on how two LED lights, 25 cameras, and 25 PCs work together to detect any defects on a glass surface.

Strip products are long workpieces such as pipes, rails, wires, or boards that are manufactured at high flow velocities. The speed of production and the small size of the object creates a big difficulty in quality control however successfully addressed by the computer inspection system as shown below for fire manufacturing.

Source: http://phys.org/news/2014-04-optical-wire-pipe-rails-meters.html

Glass sheets; another difficult application. See below figures on how two LED lights, 25 cameras, and 25 PCs work together to detect any defects on a glass surface.

Source:

Grading of lumber, cattle or chicken is a very difficult task for a computer vision system. The human eye is commonly used for this kind of application. But, a computer vision system installed near the front end of the chicken-processing line in the following figure finds the defects such as improperly bled birds and those afflicted by systemic diseases.

Source:

Grading of lumber, cattle or chicken is a very difficult task for a computer vision system. The human eye is commonly used for this kind of application. But, a computer vision system installed near the front end of the chicken-processing line in the following figure finds the defects such as improperly bled birds and those afflicted by systemic diseases.

Source: http://www.gtri.gatech.edu/casestudy/counting-their-chickens-researchers-use-machine-vi

The advantages of computer vision technology can be summarized as below.

Source: http://www.gtri.gatech.edu/casestudy/counting-their-chickens-researchers-use-machine-vi

The advantages of computer vision technology can be summarized as below.

Visual control

Visual control

Sources: http://www.graphene-lda.com/designer-portal/root-cause-analysis/case-studies/pharmas-in-the-machine.html and http://www.automation.com/library/articles-white-papers/vision-sensors-systems/packagers-choose-machine-vision-quality-inspection-to-reduce-waste-and-boost-roi

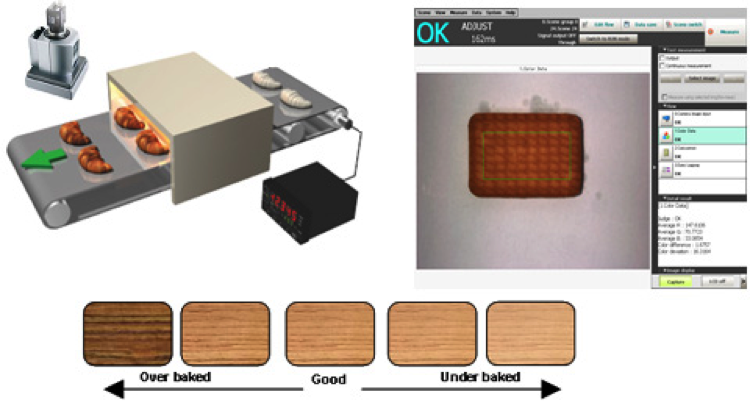

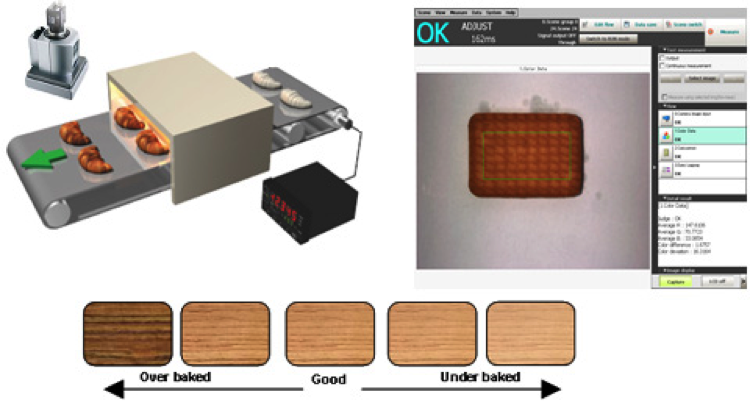

The following example demonstrate how computer vision has been used in controlling the baking quality of biscuits. In addition to the quality check for defects, the oven temperature control system gets a feedback signal for correcting the oven temperature based on the product requirement.

Source: http://www.omron.com.au/about_us/news_center/product71.asp

Painting is one of the most common applications of computer vision. For example, see the below picture on verification and defects finding of the newly painted car by using computer vision technology. Source: http://www.opli.net/opli_magazine/imaging/2013/close-inspection-of-vehicle-components-vision-2014-news/

Source: http://www.opli.net/opli_magazine/imaging/2013/close-inspection-of-vehicle-components-vision-2014-news/

Strip products are long workpieces such as pipes, rails, wires, or boards that are manufactured at high flow velocities. The speed of production and the small size of the object creates a big difficulty in quality control however successfully addressed by the computer inspection system as shown below for fire manufacturing.

Source: http://phys.org/news/2014-04-optical-wire-pipe-rails-meters.html

Glass sheets; another difficult application. See below figures on how two LED lights, 25 cameras, and 25 PCs work together to detect any defects on a glass surface.

Strip products are long workpieces such as pipes, rails, wires, or boards that are manufactured at high flow velocities. The speed of production and the small size of the object creates a big difficulty in quality control however successfully addressed by the computer inspection system as shown below for fire manufacturing.

Source: http://phys.org/news/2014-04-optical-wire-pipe-rails-meters.html

Glass sheets; another difficult application. See below figures on how two LED lights, 25 cameras, and 25 PCs work together to detect any defects on a glass surface.

Source:

Grading of lumber, cattle or chicken is a very difficult task for a computer vision system. The human eye is commonly used for this kind of application. But, a computer vision system installed near the front end of the chicken-processing line in the following figure finds the defects such as improperly bled birds and those afflicted by systemic diseases.

Source:

Grading of lumber, cattle or chicken is a very difficult task for a computer vision system. The human eye is commonly used for this kind of application. But, a computer vision system installed near the front end of the chicken-processing line in the following figure finds the defects such as improperly bled birds and those afflicted by systemic diseases.

Source: http://www.gtri.gatech.edu/casestudy/counting-their-chickens-researchers-use-machine-vi

The advantages of computer vision technology can be summarized as below.

Source: http://www.gtri.gatech.edu/casestudy/counting-their-chickens-researchers-use-machine-vi

The advantages of computer vision technology can be summarized as below.

- improved quality control (precision and repeatability prevents defective products from being shipped to customers)

- reduced labor cost

- improved productivity due to high-speed processing capability and continuous operability 24/7

- Applicability in difficult conditions (eg. Where light levels are too low or too bright for human vision, clean rooms and hazardous environments where a human cannot survive)