SHARE

Uses of Fiber Reinforced Concrete: from the NYC Subway to Mining

Research studies about concrete technology are usually associated with the discovering of new additives that improve concrete strength or durability. An example of this is the discovering of the benefits of the fibers for the concrete, such as an excellent tensile & flexural strength, a shock & fatigue resistance, ductility, and high durability. For this reason, it is not difficult to understand that the global fiber reinforced concrete (FRC) market, in terms of value, is projected to reach 3.09$ Billion by 2021.

However, the use of this additive is not new in the construction industry. Fibers have been always used in different materials with construction purposes similar to concrete-like mud-brick walls, rammed walls or lime mortars.

Let’s talk about fibers more in-depth. First, it is mandatory to classify fibers in two big groups depending on functionality, geometry or dosage since both have different applications:

Figure 1: 2nd Avenue Subway Tunnel, NY.

Figure 1: 2nd Avenue Subway Tunnel, NY.

An example of a project built with FRC could be the 2nd Avenue Subway Tunnel. While several subway lines service Manhattan’s west side, only the Lexington line services the east side carries as many as 1.5 million passengers per day. The 2nd Avenue line is now being built to alleviate this overcrowding. When completed in 2020, the twin tunnel line with 16 new stations will stretch 8.5 miles beneath Manhattan’s 2nd Avenue. The estimated final cost of $17 billion will make it the nation’s largest public works project. Figure 2: TBM used in the construction.

Figure 2: TBM used in the construction.

This fiber-reinforced concrete solution saved the contractor significant labor, time and money if compared to installing reinforcement. Despite the space limitations in the tunnel, the fiber-reinforced concrete solution allowed for the more efficient use of crews with less downtime and, more importantly, it met the specified performance parameters. Main parameters of this concrete are: Figure 3: 2nd Avenue subway line and station

Figure 3: 2nd Avenue subway line and station

Figure 4: FRC advantages in mining tunnels.

Figure 4: FRC advantages in mining tunnels.

The use of propylene microfiber concrete in tunnels construction increases the fire resistance, one of the riskiest and complex situations in this type of infrastructures due to the hard air renovation. In conclusion, the fiber reinforced concrete market is in expanding stage with a growing number of specialized companies on it because of his multiple profits. It must be considered by construction sectors that require high characteristics concrete as an alternative to traditional construction materials. Do you know any other instances where fiber reinforced concrete could be used to solve an engineering challenge?

- Microfibers: The main aim is to prevent concrete from cracking in its fresh state or before 24 hours after installation.

- Macrofibers: The main aim is to prevent hardened concrete from cracking, reduce crack width if it appears, and allow the cracked structure works.

Transport infrastructure

Specifically, transport infrastructure has benefited extensively by the main characteristics that this product offers: high durability, strong impact resistance, mechanical, chemical and thermal resistance in the construction of concrete paving, barrier rails, roads in the logistic center and sound attenuation barriers. Figure 1: 2nd Avenue Subway Tunnel, NY.

Figure 1: 2nd Avenue Subway Tunnel, NY.An example of a project built with FRC could be the 2nd Avenue Subway Tunnel. While several subway lines service Manhattan’s west side, only the Lexington line services the east side carries as many as 1.5 million passengers per day. The 2nd Avenue line is now being built to alleviate this overcrowding. When completed in 2020, the twin tunnel line with 16 new stations will stretch 8.5 miles beneath Manhattan’s 2nd Avenue. The estimated final cost of $17 billion will make it the nation’s largest public works project.

Figure 2: TBM used in the construction.

Figure 2: TBM used in the construction.This fiber-reinforced concrete solution saved the contractor significant labor, time and money if compared to installing reinforcement. Despite the space limitations in the tunnel, the fiber-reinforced concrete solution allowed for the more efficient use of crews with less downtime and, more importantly, it met the specified performance parameters. Main parameters of this concrete are:

- Water/cement ratio: 0.38.

- Cement content: 534 kg/m3.

- MasterFiber FF 3: 18 kg/m3.

- MasterFiber M 100: 1 kg/m3.

- 7-day compressive strength: 45.5 MPa.

Figure 3: 2nd Avenue subway line and station

Figure 3: 2nd Avenue subway line and stationMining

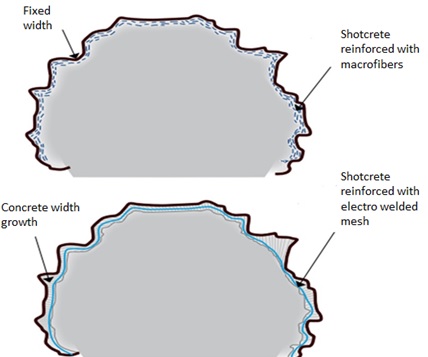

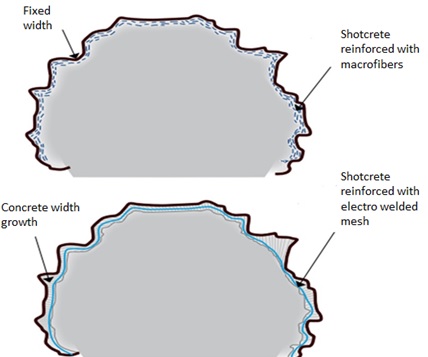

About the mining sector, particularly tunnels construction, in the shotcrete, the electro-welded mesh can be replaced by macro fibers. The growth in material costs is justified by the excavation saving time. Furthermore, this technique eliminates the obligation to cover completely the electro-welded mesh so it is possible to follow the excavation profile with a fixed concrete width saving material amounts. This advantage is shown in the next graphic: Figure 4: FRC advantages in mining tunnels.

Figure 4: FRC advantages in mining tunnels.The use of propylene microfiber concrete in tunnels construction increases the fire resistance, one of the riskiest and complex situations in this type of infrastructures due to the hard air renovation. In conclusion, the fiber reinforced concrete market is in expanding stage with a growing number of specialized companies on it because of his multiple profits. It must be considered by construction sectors that require high characteristics concrete as an alternative to traditional construction materials. Do you know any other instances where fiber reinforced concrete could be used to solve an engineering challenge?

Join our engineering community here