SHARE

2 Innovative Refrigeration Technologies for Water Recovery

The challenges everyone faces every day, just like our engineering challenges, may be approached differently and have many solutions. Nevertheless, we always have to look for the best one amongst all the feasible options. The best solution is the one that ultimately makes the difference.

Therefore, it is always useful to ask and look for information on what problem needs solving. Thus, it will be possible to replenish our solution and end up with the best one.

A good example is the challenge that just closed its first round, the Water Recovery Cooling Tower Process Challenge. This challenge looked for refrigeration technologies to recover at least 50% of the water withdrawal in a generation plant, which was quite high due to the wet way the plant was refrigerated. That way of refrigerating was the best for a while, but the available technology allows us to enhance it.

One of those is EPRI, which released a broad-based global request for information (RFI) to find potential breakthroughs related to the reduction of plant freshwater withdrawal and consumption. Their objective was to seek and develop out of the box, game changing, early stage and high-risk technologies and they received 168 proposals.

Afterwards, with the help of the National Science Foundation in some projects, EPRI funded 14 cooling and water treatment projects. Some of the most interesting ones were:

Following the investigation of these two technologies and some others, EPRI reached the conclusion that with more reasearch and funding there is a high potential to dramatically reduce water use in powerplant cooling.

As we have seen innovation is all around us, and we can find a lot of inspiration and help from many sources.

Therefore, do not waste this opportunity and take advantage of it in order to reach the optimal solution to all the challenges we propose you. Have a look at them!

Join us to help leading companies go to the next level

Following the investigation of these two technologies and some others, EPRI reached the conclusion that with more reasearch and funding there is a high potential to dramatically reduce water use in powerplant cooling.

As we have seen innovation is all around us, and we can find a lot of inspiration and help from many sources.

Therefore, do not waste this opportunity and take advantage of it in order to reach the optimal solution to all the challenges we propose you. Have a look at them!

Join us to help leading companies go to the next level

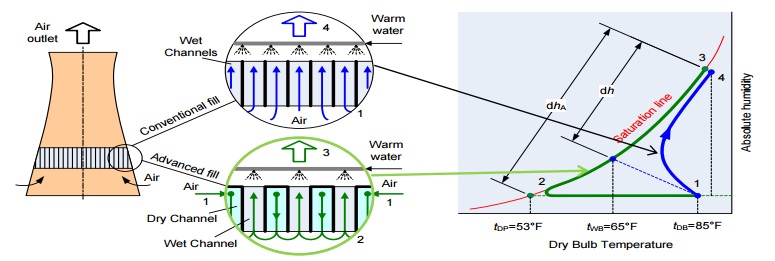

- Maisotsenko-Cycle Enhanced Cooling Towers: This system was implemented by Coolerado Corporation, which was able to produce 80% more efficient air conditioners than the ones that were in the market. They achieved that using the M-Cycle, a system that can be applied to cooling towers cooling water to dew point temperature. To do that, they use a system that consists of several plates of a special plastic that is designed to wick water on one side and transfer heat through other side. With the M-Cycle water can be cooled from 90ºF to 55,6% with an evaporation rate of 3,1% intead of reaching 72ºF with a 1,5% evaporation rate. Consequently, for the same temperature reduction, the water use would be smaller (up to a 20%).

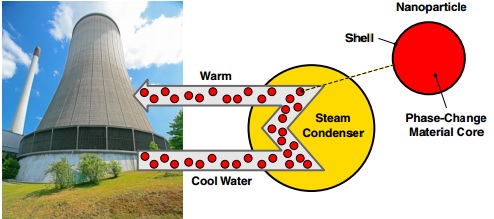

- Heat Absorption Nanoparticles in Coolant: This system is aimed to use nanoparticle technology for enhancing the thermophysical properties of heat transfer. To do that nanoparticles have to be implemented together with ceramic shells and phase change material cores. As a result, we can reach up to 20% less overall water consumption and reduce the coolant flow rates up to a 15%.

Following the investigation of these two technologies and some others, EPRI reached the conclusion that with more reasearch and funding there is a high potential to dramatically reduce water use in powerplant cooling.

As we have seen innovation is all around us, and we can find a lot of inspiration and help from many sources.

Therefore, do not waste this opportunity and take advantage of it in order to reach the optimal solution to all the challenges we propose you. Have a look at them!

Join us to help leading companies go to the next level

Following the investigation of these two technologies and some others, EPRI reached the conclusion that with more reasearch and funding there is a high potential to dramatically reduce water use in powerplant cooling.

As we have seen innovation is all around us, and we can find a lot of inspiration and help from many sources.

Therefore, do not waste this opportunity and take advantage of it in order to reach the optimal solution to all the challenges we propose you. Have a look at them!

Join us to help leading companies go to the next level