SHARE

Internet of Things & Smart Pallets for increasing productivity

IoT & Smart Pallets

There´s no doubt that smart machines, combined with the industrial IoT, are revolutionizing the manufacturing process via big data. Factories and plants using internet of things are more productive, efficient and effective than non-connected plants. Source The Lora Alliance

Source The Lora AllianceThe LoRa Alliance, welcomed revolutionary IoT solutions in the categories of "Supply Chain Optimization", "Manufacturing", "Building Automation", "Smart City", "Security", "Connected Home", "Standardization", and "Healthcare". The challenge was a huge success! With more than 2000 companies, from 150 different countries, participating. But today, we would like to talk about one of the finalist´s ideas, Palletech. Palletech is an American company, specialized in helping companies track their products ‘shipments. They work directly with pallet providers to create smart, connected pallets, allowing companies to better track their merchandise.

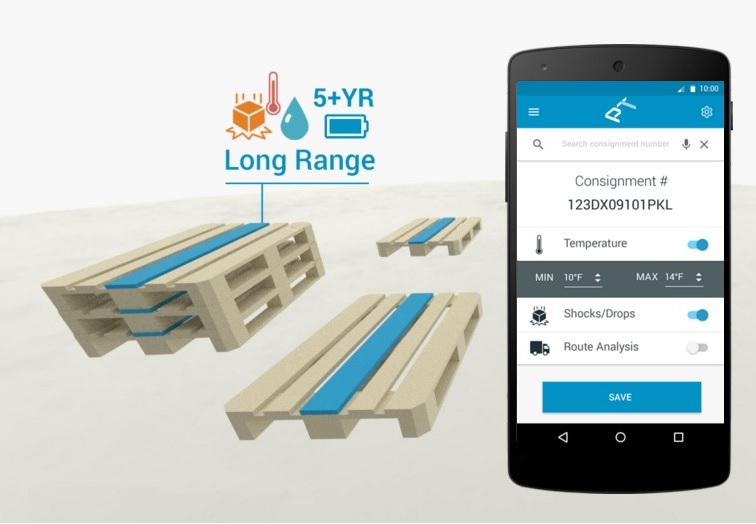

Source Palletech

Source PalletechTheir idea was to place LoRa-based sensors inside the central plank of the pallet, to collect information about temperature, location, humidity, shock, time etc. Tracking all these data in real-time improves inventory management, condition monitoring, asset tracking and security. Pallet poolers reserve up to 15% of their sales price ($10Bn per year) for manual tracking of their pallets. The value of lost and counterfeited cargo in pharma alone is worth $60Bn. $45Bn of sales are generated from fake automotive parts around the globe because of poor tracking of cargo. Currently, labels and RFIDs are used, but both are limited to scanning locations and require large infrastructure investments. With this idea, companies will have an environment where all information is available, from within the plant floor and along the supply chain, which would mean substantial savings and enhance their supply chain!