SHARE

Mining Waste Management: Reprocessing Tailings

Mining waste management: The importance of Tailings Reprocessing

Tons of excavated material are extracted every day in mines around the world but only a small percentage contains the wanted mineral. This process is called ore grade. Have you ever wondered where the leftover material goes once the valuable part has been picked out? The answer is as simple as alarming. The waste, mostly toxic because of the high concentration of heavy metals, is called tailings and is normally stored in tailing dams. This mining waste management system is very hazardous if the tailings are not treated properly. There are at least 3,500 of these structures that remain active in the world, although the exact figure is still unknown. Only in Chile, there are 696 registered, a seventh of them active. If the mining industry wants to make operations more sustainable, solutions to clean up these tailings and make the most of the valuable minerals are urgently needed. It is of the utmost importance to prevent disasters like the one in Bento Rodrigues (Brazil) in 2015, where 60 million cubic meters flowed down the river Doce to the Atlantic Ocean. It is known as the worst environmental disaster in Brazil's history.

Thanks to the progress in technology, the reduction of ore grades, and a more environmentally friendly vision, companies are starting to care more about mining waste management by reprocessing tailings to increase their value.

Let's take a look at some reprocessing projects around the world:

It is of the utmost importance to prevent disasters like the one in Bento Rodrigues (Brazil) in 2015, where 60 million cubic meters flowed down the river Doce to the Atlantic Ocean. It is known as the worst environmental disaster in Brazil's history.

Thanks to the progress in technology, the reduction of ore grades, and a more environmentally friendly vision, companies are starting to care more about mining waste management by reprocessing tailings to increase their value.

Let's take a look at some reprocessing projects around the world:

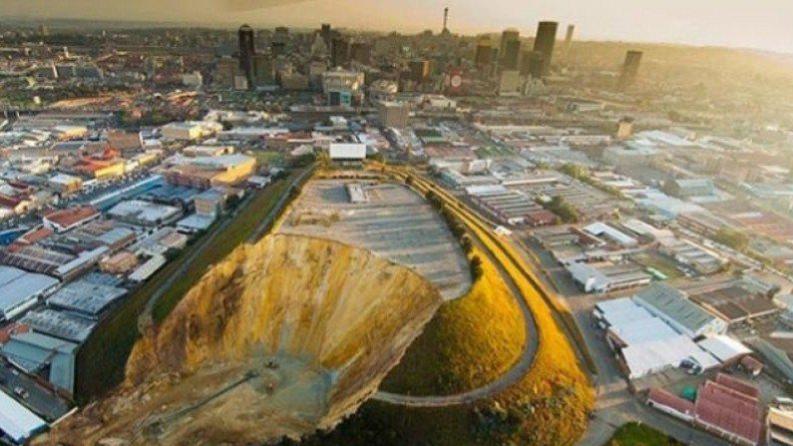

West Rand Tailings Retreatment Project (WRTRP) in South Africa

Through a combination of tailings storage facilities, the company estimates there to be 6.2 Moz of gold and 97.2 Mlb of uranium. Key to the successful execution of this project is the permitting and construction of a high-volume capacity network of pipelines connecting reclamation stations, thickeners, and processing plants for economical extraction of gold andPan African Resources

Also working on a gold tailings retreatment project in South Africa. The project intends to retreat old tailings at a rate of one million tonnes per month and aims to recover about 688,000 ounces of gold from the combined tailings deposits over the life of the project.Metals X Limited

Also, recently announced that the updated Definitive Feasibility Study (DFS) for their Renison Tailings Retreatment Project estimates it to be a lucrative endeavor with high margins. The company projects that they will be able to recover around 5,400 tonnes of tin and 2,200 tonnes of copper annually. This project is located in Australia. In conclusion, it is clear that it is possible to recover minerals from the tailings thanks to the new technological inventions, like the solutions submitted for this mine waste management challenge. Do you know any other techniques or projects related to reprocessing tailings?

Join our engineering community here

In conclusion, it is clear that it is possible to recover minerals from the tailings thanks to the new technological inventions, like the solutions submitted for this mine waste management challenge. Do you know any other techniques or projects related to reprocessing tailings?

Join our engineering community here