SHARE

7 Types of Robot Grippers and their Industrial Applications

Robot Grippers and their Industrial Applications

In this post about robot grippers (also known as end-effectors), you can find a compilation of different types of robot grippers, their uses in the industry and some aspects that usually go unnoticed.

There is a question that every engineer must ask himself when automating a process. Once the robot has been chosen, which one would be the perfect gripper? If the product to be picked is not too delicate, there are several options available but, if we must be smooth, the situation changes. Besides, the manufacturing of custom-made robot grippers is not cheap, there are no guarantees that it will effectively work and its specific programming and adaptation is resource-consuming.

Fortunately, the world of robotics has changed a lot and there are more and more kits available, so we can find the product we need for our industrial process and install it ourselves very easily.

Universal Robots was a pioneer in opening up their system to other manufacturers, in an open way, and this strategy has paid off with a multitude of products and kits that we can use in their cobots for most industrial applications. They have also increased the designs available for do-it-yourself manufacturing, thanks to the rise and cost reduction of 3D printers, which increases the possibilities for customisation to almost limitless extremes.

Here you will find the different types of robot grippers that are most important on the market right now, and some newer ones that are not yet widely used.

If you want to stay tuned for our robotics and automation challenges, check out our recent challenges section.

Types of Robot Grippers

1. Robot grippers with 2 fingers

These are the simplest robot grippers, suitable for many industrial products and easy to manufacture. Within this group, different alternatives can be found: with opening control, pressure control, with distance control in the opening and closing, picking up pieces by inserting the two fingers inside a hole. They can also have pneumatic or electric actuation. Our favorite models are the one from On-Robot and Robotiq, with its Plug & Play feature in the Universal Robots that makes them easy to use in a factory. Actually, during the Ennmotive Hackathon Industry 4.0 there were people that programmed them for the first time with no previous knowledge. The one from On-Robot can have two grippers on one wrist, which expands the handling possibilities enormously, and also works independently.

2. Grippers with 3 fingers

This type of robot gripper is not used that often since most automation cases can be solved with a two-finger gripper. However, when it is necessary to pick up delicate objects with strength and precision, three fingers grippers are the solution (take a look at this video with the robotiq adaptive gripper for fresh food). Besides, they adapt even better to non-flat surfaces with articulated fingers. This kind of robot grippers is essential when there are many different pieces to pick up since a versatile and adaptable gripper is needed. Obviously, the greater the complexity, the higher the price of the gripper, which doubles the two-finger grippers' price. An example of the use of these grippers is the handling of long tubes since it can improve the alignment and efficiency in the quick spins. There are also grippers with tiny non-articulated fingers which are much cheaper and can pick small cylindrical objects.

Some examples are:

Visit the Universal Robots website for a grippers compilation and the links to request a budget.

3. Robot grippers with flexible fingers

The robot grippers with flexible fingers are newer and more fit to pick up different objects. Although they are more limited in general regarding the volume and weight of the object to be picked, they are perfect for delicate things, like food.

These 'soft robots' handle food with care pic.twitter.com/5aoegVWpBr

— Tech Insider (@techinsider) April 3, 2018

There are a few simple ones, based on a sheet structure, like Festo Multi Choice Gripper, that also can be used for parallel grippers, or the one from Kuka, fairly similar, designed to be used with cobots.

Check out the ennomotive blog for more posts about robotics innovations, don’t miss out!

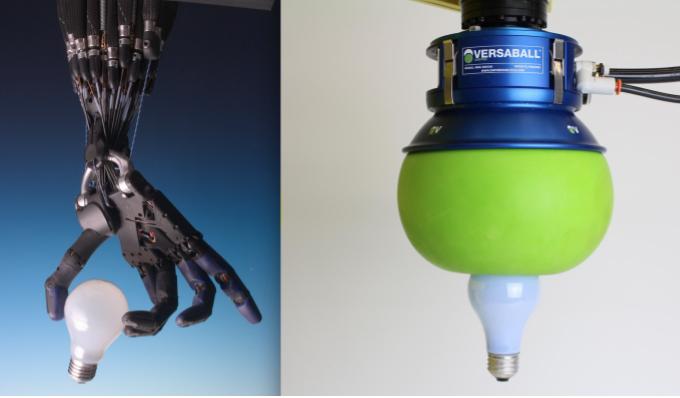

4. Grain-filled flexible ball

This latex balloon filled with grain lays on the object to be picked, sucks in the air of the balloon and turns into a rigid shape that holds the object without damaging it. It caused quite a shock after it was released due to its simplicity, concept, and versatility. See an example in this video from iRobot:

There have been variations afterward, depending on the object to be picked. The variations include the diameter of the balloon and the filling: ground coffee, rice, coffee beans, etc. This is a video with the robot gripper from Cornell University.

There is a similar variation gripper from Festo, made of silicone and a double chamber of gas and water, based on a chameleon's tongue.

5. Big robot grippers for palletizing

The progress here was made regarding standardization since it is possible to purchase different predefined types of grippers. There is also an increase in capacity and variety. Here are some examples from ABB, a strong player in the handling of heavy loads.

What's coming

Although its use is not industrial yet, it may be very soon thanks to the speed at which the robot grippers are being developed. It is quite interesting to see the use of 3D printing in manufacturing since it adds the benefits of the individualized design and easy maintenance.

6. Semi-professional 3D printed Robot Grippers

There are semi-professional 3D printed robot grippers in design platforms such as Grabcad and Autodesk Academy, among others, that can be instantly manufactured by the user. These can be used as long as the necessary strength is not excessive and the objects are light enough, which relegates these grippers to the semi-professional and academic atmosphere. Take a look at this 3-finger version printed by Materialise in Expo Milano 2105.

7. Experimental Robot Grippers

Festo has been working for a few years now on bionic grippers, inspired by nature, through Bionic Learning Network, which resulted in the Octopus Gripper. A different model is the EPFL rubber clamp made with five layers of materials: pre-stretched rubber between two layers of electrodes, which make the fins curve outwards when they are off.

Before you go, we have one more question for you:

What kind of robot gripper can move heavy tubes inside a factory? At ennomotive, we have already solved this challenge, read more about it here.