SHARE

3 Sustainable Trends in 3D Printing Materials

It may as well be science-fiction, but it is real. 3D printing materials are changing the way the world is built. Its diverse products range from ceramic blocks that refresh the atmosphere to organic knittings, and even orthopedic prosthesis. 3D printing represents one of the big technological bets in today's technological world, thanks to its ability to create practically any object.

According to the estimations of a study conducted by OBS Bussiness School consulting, the value that this industry produces reaches 188,5 million euros.

Like all disruptive technologies, the 3D printers keep in a continuous development with the objective to find new applications or new 3D printing materials.

If we focus on the printing materials, we can see an evolution since the creation of this kind of printing technique. When we talk about the 3D printers, we usually think of the use of plastics (ABS or PLA). However, we would like to present you with other alternative materials:

Do you know any new materials for 3D printing that is being developed? Do you know materials for 3D printing with a polymer base inferior to the 20%? Share them with our community!

Join our engineering community here

Do you know any new materials for 3D printing that is being developed? Do you know materials for 3D printing with a polymer base inferior to the 20%? Share them with our community!

Join our engineering community here

3D Printing Materials

Metals

A growing number of metals and compounds of metal are used as 3D printing materials in the industry. Two of the most common are aluminum and the derivatives of cobalt. Other stronger metals and also commonly used are the stainless steel and the titanium as dust. In the last two years, gold and silver have been added to the variety of metal materials that can be directly printed in 3D, with applications in jewelry. Many metals have their fusion point over the 500°C, for that reason, the 3D printers for metals are expensive and potentially dangerous if they're not used properly.

LayWoo-D3

It's a filament of printing invented by Kai Party to be used with printers of RepRap wire. The printing material is made of recycled wood in a 40% and polymers that connects the particles of wood. The resultant material has a durability similar to the PLA and can be printed at temperatures between 175° and 250°C.

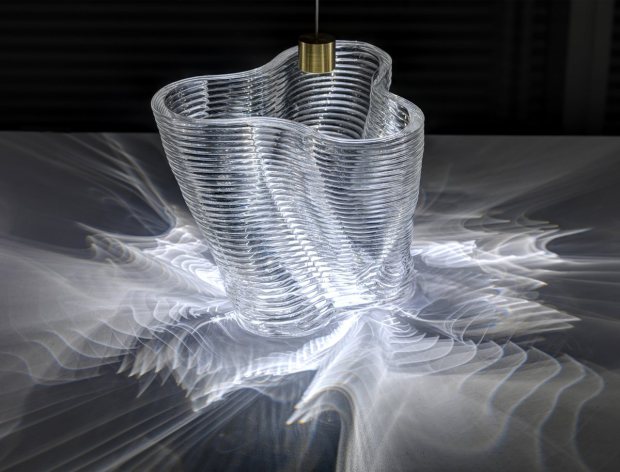

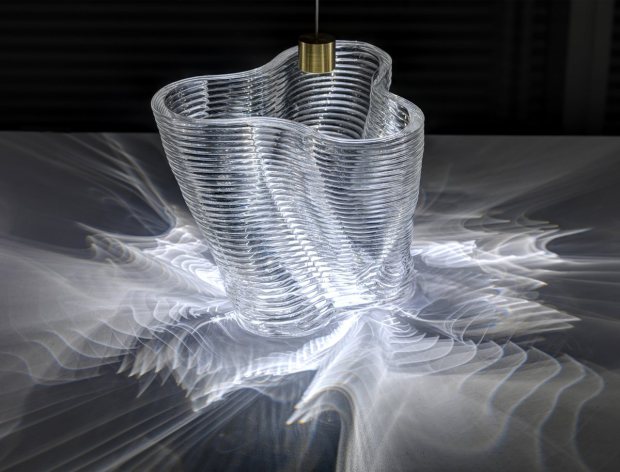

Glass

The MIT's Media Lab had to adapt the traditional methods of glass production so it can work in the 3D printing to work with this material. The result was the G3DP (Glass 3d printing) a machine capable of printing transparent optical glass. It works with two heat cameras, the upper camera, that consists of a crucible oven where the material is stored and an extrusion made of aluminum, zirconium, silicon, able to handle temperatures until the 1037°C, which are necessary to control the viscosity of the material. The glass is put over the lower camera, which is the one that must regulate the temperature between 480° and 515°C to reduce the stress in the structures of the piece. Do you know any new materials for 3D printing that is being developed? Do you know materials for 3D printing with a polymer base inferior to the 20%? Share them with our community!

Join our engineering community here

Do you know any new materials for 3D printing that is being developed? Do you know materials for 3D printing with a polymer base inferior to the 20%? Share them with our community!

Join our engineering community here