SHARE

4 Low-Cost Ventilation Systems to treat COVID-19 Patients

In March, ennomotive launched a challenge aimed at lending a hand in the ongoing COVID-19 pandemic. The goal was to come up with a new low-cost, reliable and easy-to-manufacture ventilator model, one that helps hospitals alleviate their urgent need for ventilation systems for coronavirus patients.

We are extremely grateful for all those who participated, all 101 of you. Your support and ideas during these troubling times are very much appreciated. We have received different kinds of solutions, most of which can be included in one of the following groups:

Hugh Potts from the UK, proposes a similar solution with some differences like an oxygen mixing chamber and rotating valves to avoid logistical problems.

Hugh Potts from the UK, proposes a similar solution with some differences like an oxygen mixing chamber and rotating valves to avoid logistical problems.

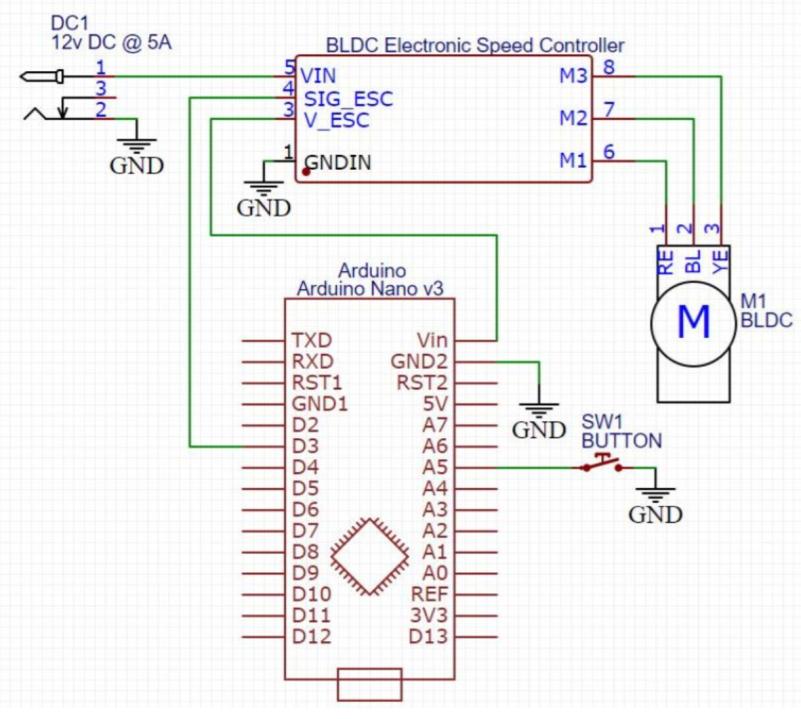

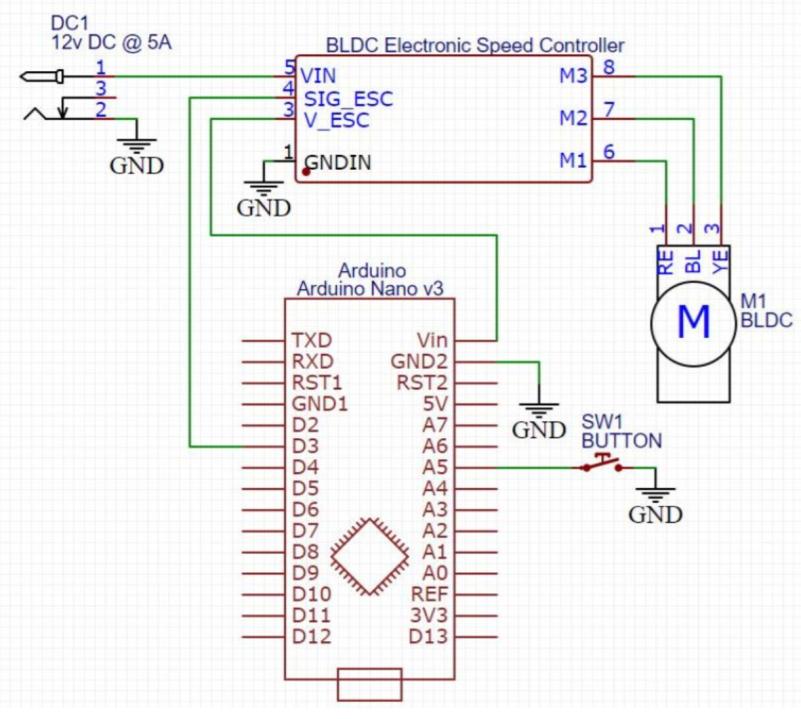

Andrew Piscione proposes to use a standard car blower controlled by an Arduino nano.

Andrew Piscione proposes to use a standard car blower controlled by an Arduino nano.

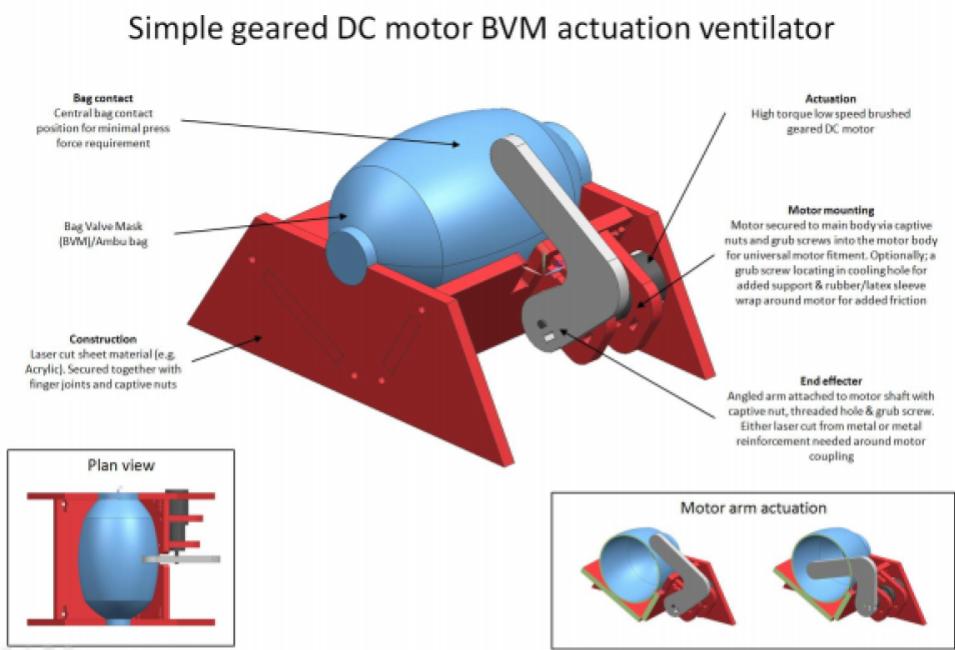

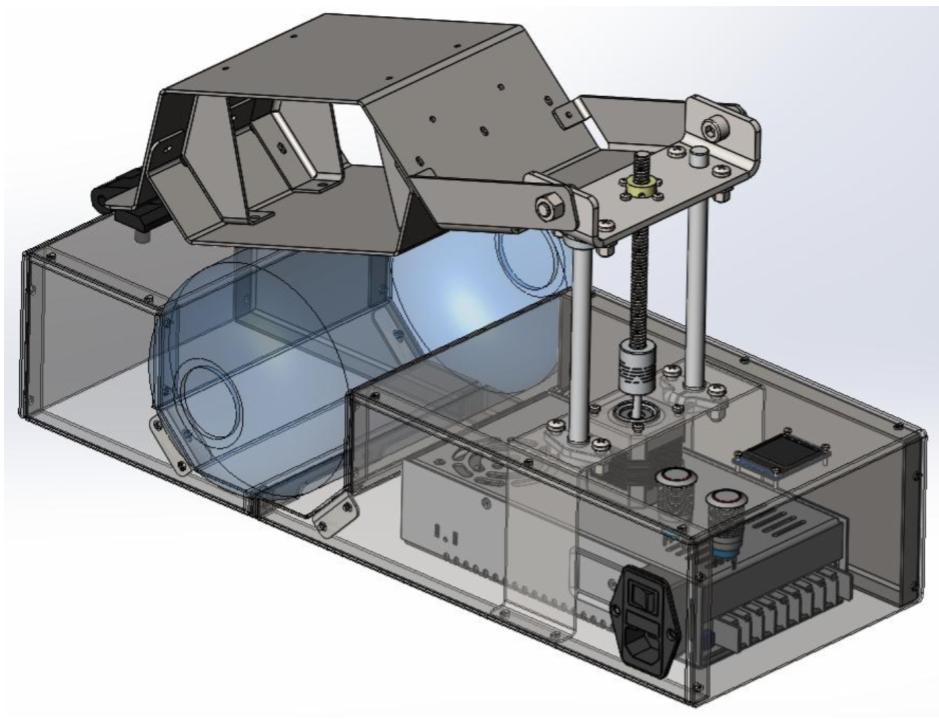

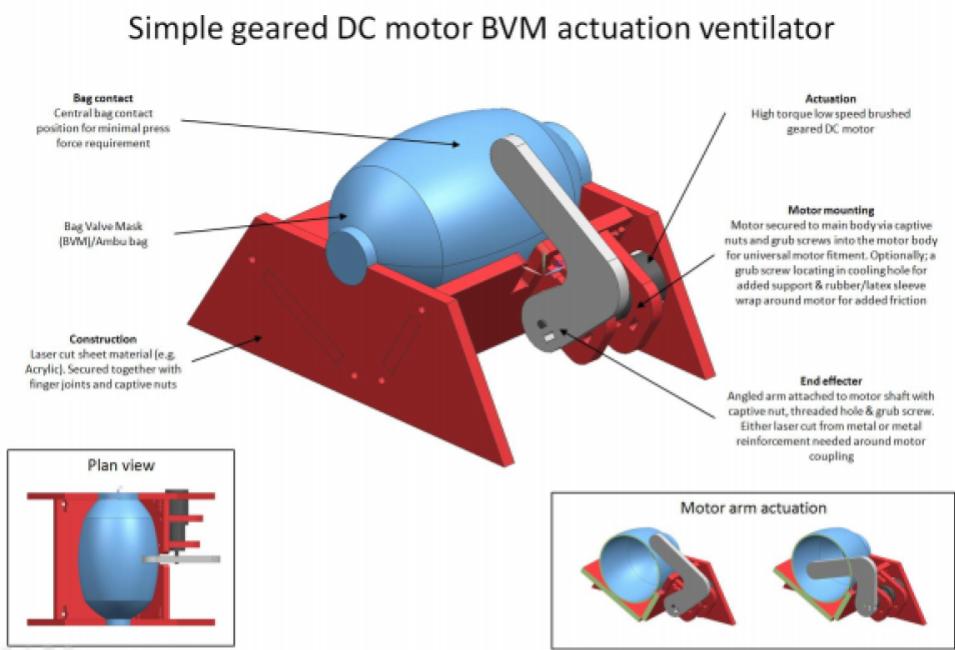

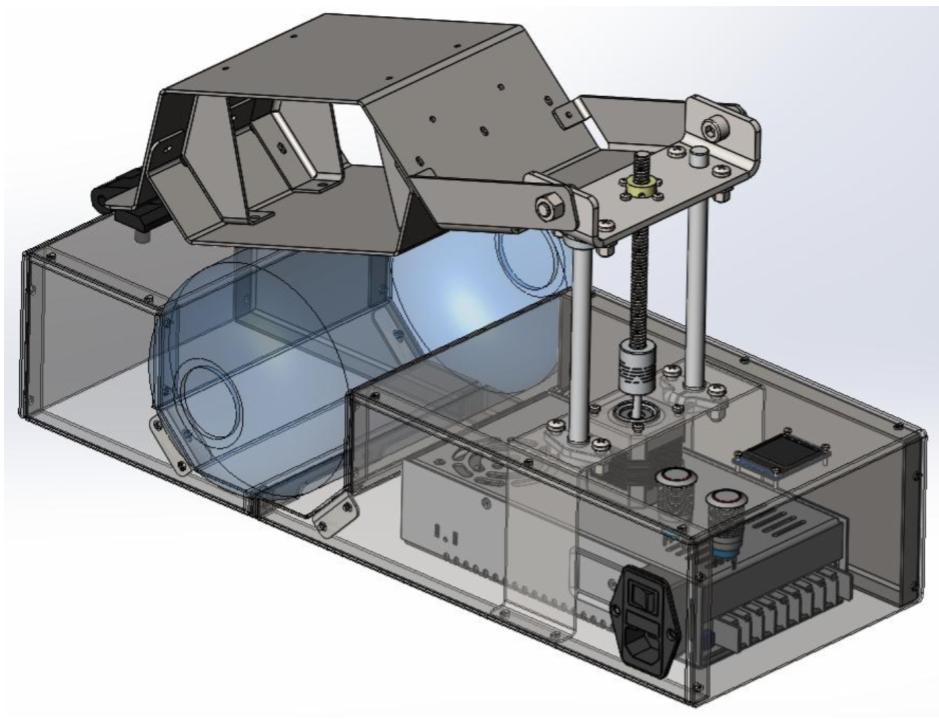

Other, more sophisticated solutions of this type have also been proposed, notably, the one suggested by Darren Lewis. In this case, a custom mechanical system is employed to operate the AMBU bag. By the adaptation of a common DC motor and combining it with a microcontroller, a high degree of control over the respiration process can be achieved. These sorts of solutions, while attractive, require a certain manufacturing infrastructure that the previous solution does not, which may slow down their implementation. Given the current circumstances, time is of the essence, so how quickly the solution can be deployed must also be considered.

Other, more sophisticated solutions of this type have also been proposed, notably, the one suggested by Darren Lewis. In this case, a custom mechanical system is employed to operate the AMBU bag. By the adaptation of a common DC motor and combining it with a microcontroller, a high degree of control over the respiration process can be achieved. These sorts of solutions, while attractive, require a certain manufacturing infrastructure that the previous solution does not, which may slow down their implementation. Given the current circumstances, time is of the essence, so how quickly the solution can be deployed must also be considered.

Maksym Gaievskyi from Ukraine proposes a similar solution.

Maksym Gaievskyi from Ukraine proposes a similar solution.

We have another design from Allison and Robert Kaminski, which does away with the microcontroller and instead opts for a timed power outlet to regulate the ventilation cycle and uses solenoid valves as actuators. This solution is promising for how easy it is to acquire the necessary components, but relying on a timed relay, which is not easy to manipulate quickly, might make it unwieldy.

If you want to read more about this Pressure Ventilator Challenge, we have prepared a summary of the process.

We have another design from Allison and Robert Kaminski, which does away with the microcontroller and instead opts for a timed power outlet to regulate the ventilation cycle and uses solenoid valves as actuators. This solution is promising for how easy it is to acquire the necessary components, but relying on a timed relay, which is not easy to manipulate quickly, might make it unwieldy.

If you want to read more about this Pressure Ventilator Challenge, we have prepared a summary of the process.

Centralized air ventilation systems

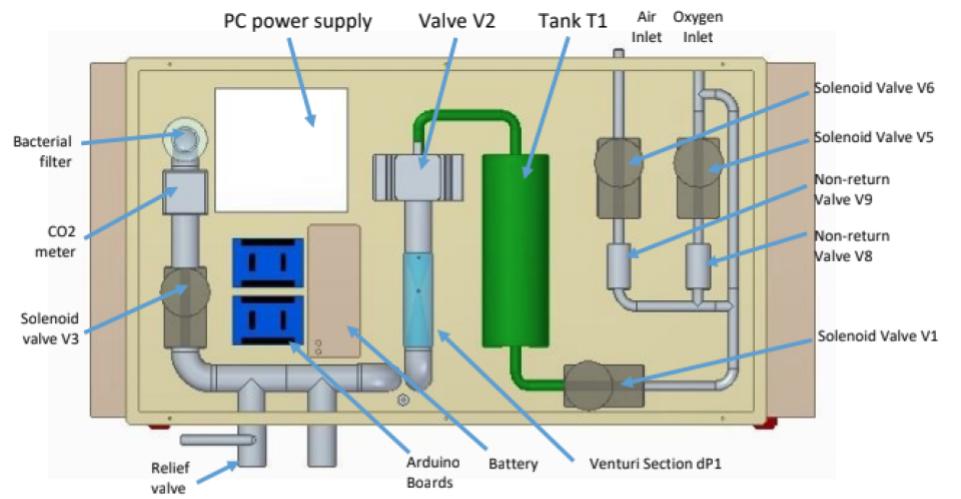

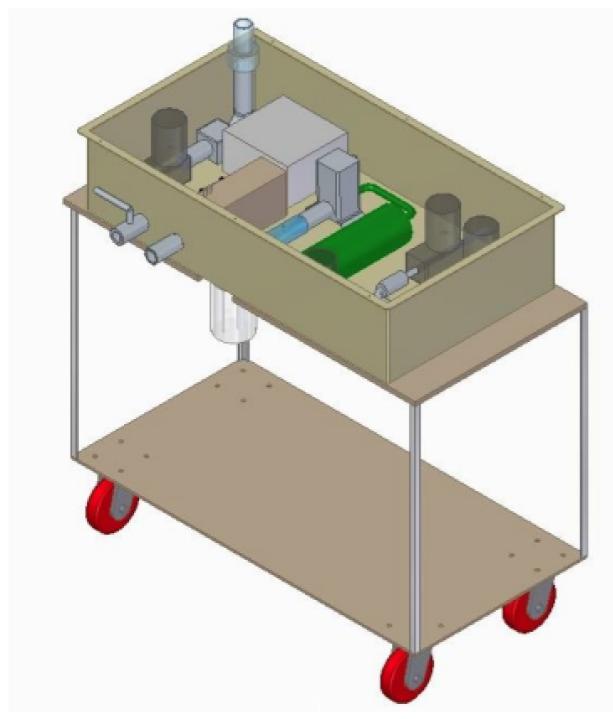

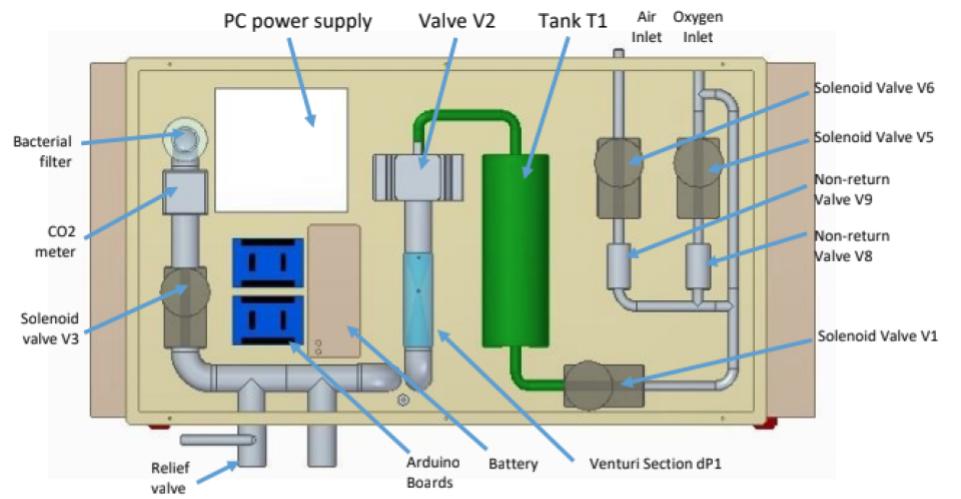

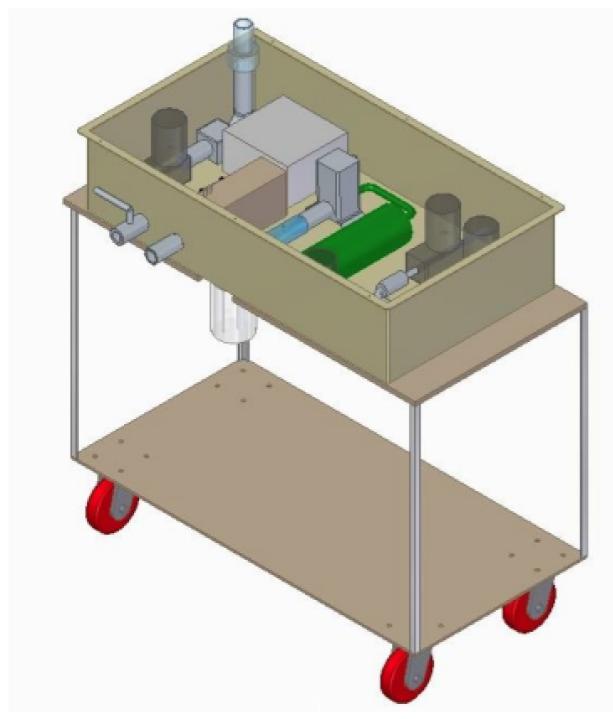

Firstly there are centralized air supply solutions. These solutions generally use an industrial oil-free air compressor (or similar) to provide air to 10-20 patients at a time. The air is then mixed with the oxygen required by the patients, extracted from standard oxygen bottles. The air received by each patient is regulated by individual valves connected to microcontrollers and monitored for each patient. These solutions are suitable for intubated patients, the most vulnerable. The top-rated solution of this category, proposed by Frede Jensen, is especially promising and is the one we are currently focusing on. At Ennomotive, we have launched a new challenge where you can read the details of this design and propose new additions and improvements to perfect the ventilator. If you want to participate in this challenge, please join and submit your improvements. While a requirement of this solution is the usage of an air compressor to supply several patients with air at once, there are several different designs when it comes to designing the terminal to which each individual patient is connected. One such solution is proposed by the team led by Nicolás and Emanuel Giménez. Their design integrates the air quality monitoring and valve control aspects all in one device. This device is mounted onto a small trolley and made from relatively inexpensive and readily available components, making it a suitable complementary solution for the one described before. It uses Arduino boards as controllers and solenoid valves as actuators, alongside other mechanical components such as tanks and bacterial filters to ensure all specifications are met.

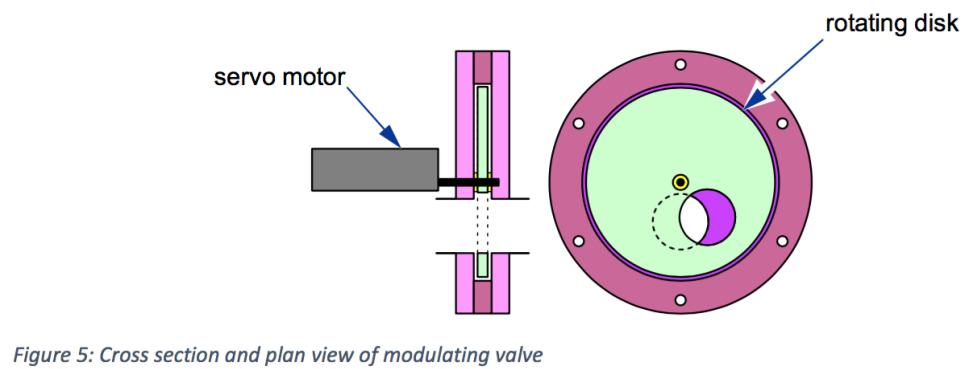

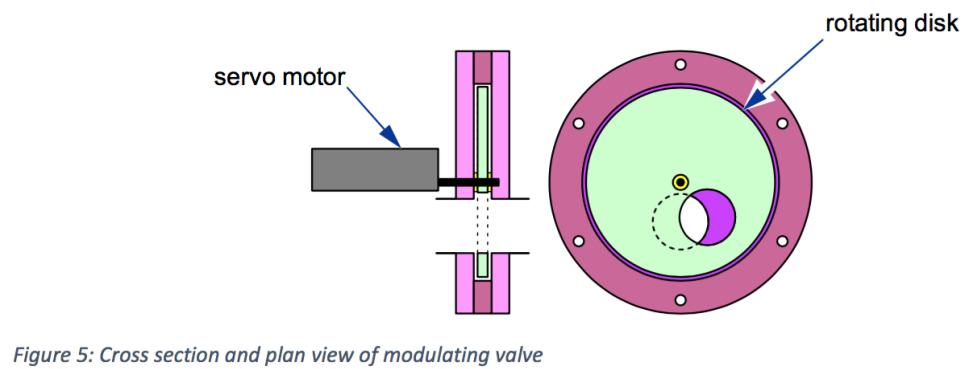

Hugh Potts from the UK, proposes a similar solution with some differences like an oxygen mixing chamber and rotating valves to avoid logistical problems.

Hugh Potts from the UK, proposes a similar solution with some differences like an oxygen mixing chamber and rotating valves to avoid logistical problems.

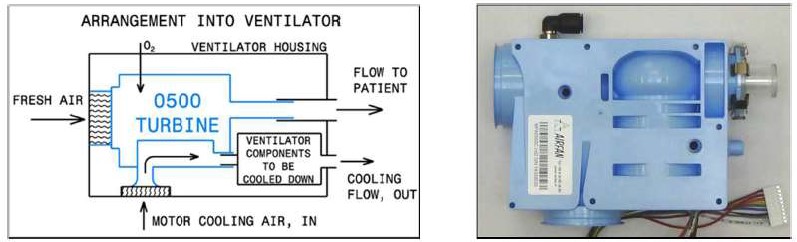

Using a blower

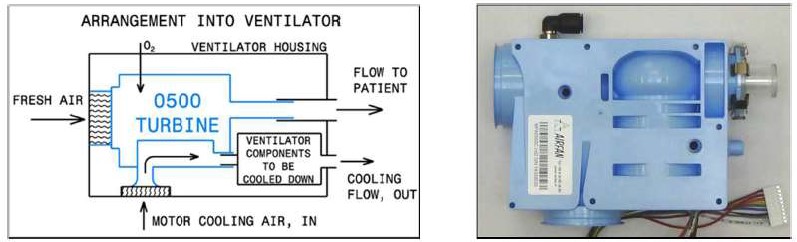

Some solutions propose employing a blower or feeding the air to individual patients. This type of solution is particularly suitable when a patient needs to be moved from one spot to another. However, it may not be as cost-effective as the previous type when treating multiple patients. Out of these solutions, the one proposed by Edgar Boada, from Argentina, is the most complete one. This solution employs a miniature turbine where the air intake and oxygen are mixed in a single step, with a 3d-printed housing box for all components. Andrew Piscione proposes to use a standard car blower controlled by an Arduino nano.

Andrew Piscione proposes to use a standard car blower controlled by an Arduino nano.

The AMBU bag type

These solutions aim to continuously pump a standard AMBU bag. Their goal is to assist with the breathing of patients that do not require intubation and unburden medical staff of said task. A wide variety of designs have been proposed for this type of solution, but the one that caught the most attention from the evaluators has been suggested by Dr. Siavash Ahmadi-Noorbakhsh. This solution intends to use standard sphygmomanometers, used to determine blood pressure, and electronically control them to expand and contract while wrapped around an AMBU bag. The main advantage of this solution is that its materials are already available in hospitals. Other, more sophisticated solutions of this type have also been proposed, notably, the one suggested by Darren Lewis. In this case, a custom mechanical system is employed to operate the AMBU bag. By the adaptation of a common DC motor and combining it with a microcontroller, a high degree of control over the respiration process can be achieved. These sorts of solutions, while attractive, require a certain manufacturing infrastructure that the previous solution does not, which may slow down their implementation. Given the current circumstances, time is of the essence, so how quickly the solution can be deployed must also be considered.

Other, more sophisticated solutions of this type have also been proposed, notably, the one suggested by Darren Lewis. In this case, a custom mechanical system is employed to operate the AMBU bag. By the adaptation of a common DC motor and combining it with a microcontroller, a high degree of control over the respiration process can be achieved. These sorts of solutions, while attractive, require a certain manufacturing infrastructure that the previous solution does not, which may slow down their implementation. Given the current circumstances, time is of the essence, so how quickly the solution can be deployed must also be considered.

Maksym Gaievskyi from Ukraine proposes a similar solution.

Maksym Gaievskyi from Ukraine proposes a similar solution.

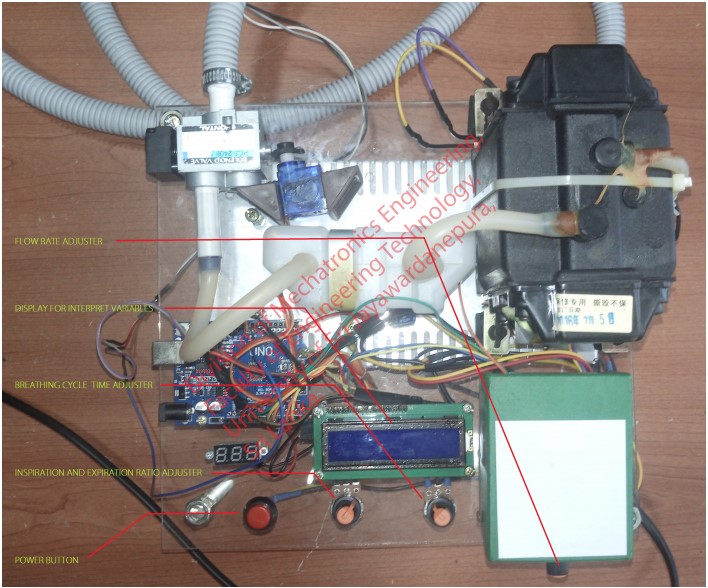

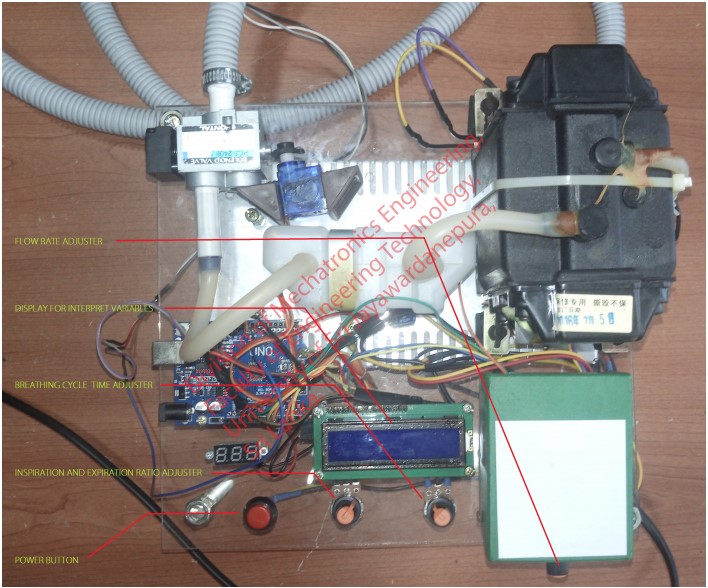

The air pump type

This solution is similar to those that use blowers. However, it needs easily-available air pumps (like aquarium air pumps) to supply the necessary airflow. The critical factor for these solutions is ensuring that the maximum airflow requirements are met. Therefore, it may not be suitable for patients in the most dire conditions but it could still be used by many others. P.D.S Ashan Kumara, from Sri Lanka, has designed an ingenious device, using a repurposed air pump from a soldering station in conjunction with an Arduino (both very easily accessible technologies right now) to create a ventilator. We have another design from Allison and Robert Kaminski, which does away with the microcontroller and instead opts for a timed power outlet to regulate the ventilation cycle and uses solenoid valves as actuators. This solution is promising for how easy it is to acquire the necessary components, but relying on a timed relay, which is not easy to manipulate quickly, might make it unwieldy.

If you want to read more about this Pressure Ventilator Challenge, we have prepared a summary of the process.

We have another design from Allison and Robert Kaminski, which does away with the microcontroller and instead opts for a timed power outlet to regulate the ventilation cycle and uses solenoid valves as actuators. This solution is promising for how easy it is to acquire the necessary components, but relying on a timed relay, which is not easy to manipulate quickly, might make it unwieldy.

If you want to read more about this Pressure Ventilator Challenge, we have prepared a summary of the process.

Let us know about other types of ventilation systems for COVID-19 and explore what ennomotive has to offer.